In advanced manufacturing processes like vacuum infusion molding (VIM), ensuring a perfect seal is critical for producing high-quality composite parts. The vacuum guide sealing rubber strip plays a vital role in this process by preventing resin leaks and maintaining consistent vacuum pressure.

This specialized rubber strip is placed between the mold and the parts being formed, creating an airtight seal that allows resin to evenly penetrate reinforcement materials (such as fiberglass or carbon fiber). It is widely used in manufacturing wind turbine blades, yachts, automotive components, and aerospace parts, where precision and defect-free molding are essential.

How Does a Vacuum Guide Sealing Rubber Strip Work?

1. Sealing Mechanism: Compression Under Vacuum Pressure

• The rubber strip is positioned along the edges of the mold where sealing is required.

• When vacuum pressure is applied, the strip gets compressed and deformed, filling all gaps and voids.

• This creates a hermetically sealed chamber, preventing air ingress and resin leakage.

2. Ensuring Uniform Resin Distribution

• Once sealed, liquid resin is injected into the mold.

• The vacuum ensures the resin penetrates evenly into the reinforcement material (e.g., fiberglass, carbon fiber).

• Without a proper seal, resin could leak, leading to weak spots, air bubbles, or defective products.

3. Applications in Composite Manufacturing

✔ Wind Turbine Blades – Ensures consistent resin infusion for structural integrity.

✔ Marine Industry (Yachts & Boats) – Prevents delamination and improves durability.

✔ Automotive & Aerospace Parts – Critical for lightweight, high-strength components.

✔ Industrial Composites – Used in tanks, pipes, and other fiber-reinforced structures.

Key Features & Customization Options

Material Composition: Environment-Friendly Butyl Rubber

• Excellent elasticity – Maintains seal under high vacuum pressure.

• Chemical resistance – Withstands exposure to resins, solvents, and

adhesives.

• Temperature stability – Performs well in varying curing conditions.

Standard & Customizable Specifications

|

Parameter |

Standard Options |

Customization Available? |

|

Thickness |

2mm – 3mm |

Yes (upon request) |

|

Width |

10mm – 12mm |

Yes |

|

Length |

15m – 20m per roll |

Yes (bulk orders) |

|

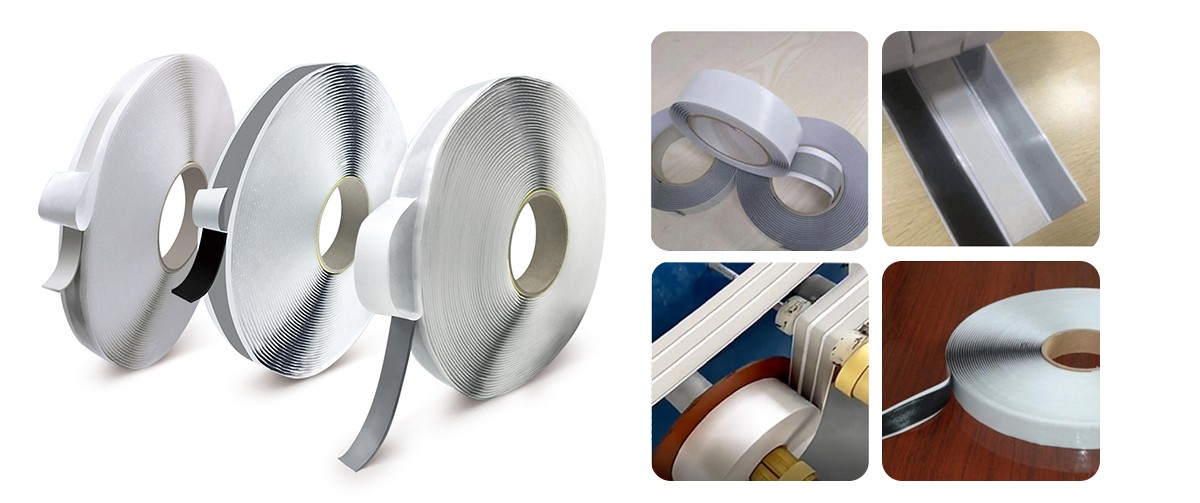

Color |

Black, Gray, White |

Yes (special colors) |

| Release Film | Glasin Paper, Kraft Paper | Yes (alternative liners) |

Why Choose High-Quality Vacuum Sealing Strips?

1. Prevents Resin Leakage & Air Entrapment

• A poor seal can lead to voids, weak spots, and failed infusions.

• High-quality butyl rubber ensures zero leaks, improving product consistency.

2. Reusable & Durable

• Unlike cheap foam seals, butyl rubber strips maintain elasticity over multiple uses.

• Resistant to tearing, cracking, and compression set.

3. Customizable for Specialized Applications

• Need a wider, thicker, or colored strip? Manufacturers can tailor dimensions.

• Different release films (Glasin/Kraft paper) prevent sticking during handling.

The vacuum guide sealing rubber strip is a small but crucial component in vacuum infusion molding, ensuring leak-free resin distribution and high-quality composite parts.Whether for wind energy, marine, automotive, or aerospace applications, selecting the right sealing strip improves production efficiency and product reliability.

Looking for custom vacuum sealing solutions? Contact us today for high-performance butyl rubber strips tailored to your needs!

Post time: Jun-27-2025